What is top-load testing?

Also known as column-crush, vertical load resistance and axial force resistance, top-load testing involves applying a downwards compressive force to a packaging container and measuring its resistance to deformation.

More businesses than ever are focused on protecting the environment by reducing overall packaging and making it more recyclable.

Innovation through new materials and improved packaging design are contributing greatly to light-weighting and sustainability initiatives, but critically they must do this without compromising a container's overall strength or performance. That's where top-load testing comes in as a key method for performing quality control.

Mecmesin Top-Load Testers provide reliable and accurate solutions for evaluating new packaging design in R&D and performing routine quality checks, often being installed in QC labs and production areas next to the filling lines.

A bench-mounted top-load tester provides essential data for establishing acceptance specifications for newly developed designs plus in day-to-day batch control for quality purposes.

How is 'top-load' tested?

Test methods vary but all define the speed of compression and how far the package should be deformed. The peak force is typically recorded to determine the product's strength.

Since various standards call for deforming a container by a set distance, it is important that a top-load tester can accurately detect the initial height of the sample, and reliably move by the correct distance.

It is important that you take account of the test method when using data for comparative purposes, for example...

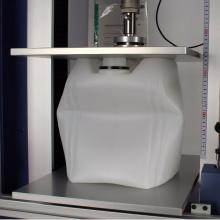

Vented vs non-vented plastic bottles

A top-load test of an empty plastic bottle using a non-vented method will trap air inside the bottle, causing a higher peak force value than a bottle tested using the vented method (that allows air to be released during the test).

Cardboard container vs cardboard materials

For multi-wall cardboard materials it may be necessary to take a standard sample of the material rather than the whole container.

These samples are assessed for rigidity by Edge Crush testing held as being predictive of final construction strength.

Product performance

Top-load (or Column-crush) testing ensures that packaging products consistently meet the requirements for resisting the axial load exerted during:

- Production

Bottles, for example, must withstand the stresses of filling and capping. - Storage and display

Almost all packaging is stacked (palletized) at some point, in both empty and filled states. Top-load testing helps calculate how many pallets can be stacked during storage. - Transport

Extra stress is frequently experienced when packaging is subject to movement or when other products are placed on top. Packaging must be sufficiently robust to maintain integrity to industry standards when subject to these stresses.

Failure to meet these objectives can result in unacceptable levels of packaging failure which lead to:

- product leakage or total breakage for the consumer

- high product return rates for the manufacturer

- wastage and harmful environmental impact

Cost-effective design

In order to achieve optimum performance and meet corporate environmental-protection, manufacturers strive to “lightweight” or “down-gauge” packaging materials as far as possible while still ensuring that the package provides adequate product protection and is recyclable.

The down-gauging of billions of packaging products worldwide amounts to considerable cost savings by reducing the volume of raw materials but it places an extra onus on 'designing for strength'.

Plastic bottles and containers, cans, glass jars, or cardboard cartons, will all behave differently according to the materials used, the structural design of the container and, of course, its contents.

A common example of a stacked container is the plastic bottle, often made from HDPE or PET, and used globally as a container for beverages, oils, cleaning fluids and other liquids/gels. It has design features that affect axial load strength, including the closure, handles, grip areas, and the shoulder and base design. Some designs are made to improve nesting for unit-to-unit stacking and to increase stack stability.

As an example, the weight of the typical 500ml drinks bottle has been halved in the last 15 years, thanks to technologists..... but they couldn't have done it without Top-load testing !

Use top-load testing as an integral part of the design process to ensure the most effective use of raw materials and for quality-control testing at your production line.

Our most popular top-load testers at a glance

MultiTest-dV

Capacity

0 - 2.5 kN

Type

Machine or Software control

Automated control

No

Data analysis

Basic

OmniTest Touch 0.5/1/2.5

Capacity

0 - 50 kN

Type

Software control - VectorPro

Touchscreen

Optional

Automated control

Yes

Data analysis

Advanced

OmniTest Touch 5/7.5

Capacity

0 - 7.5 kN

Type

Software control - VectorPro

Touchscreen

Optional

Automated control

Yes

Data analysis

Advanced

OmniTest 10/25/50

Capacity

0 - 50 kN

Type

Software control - Emperor

Touchscreen

Optional

Automated control

Yes

Data analysis

Advanced

Common features

Environment

Quality Control

Research & Development

Production

2 Year Warranty

Data output

Pass/fail indicator

Data analysis

Software: VectorPro

Features of top-load testing

Key to reliable top-load testing is working to a recognised method, which provides an accurate control of the test speed to compress the package to a pre-set deformation or break point.

Precise measurement of the compressive force and the package deformation is essential together with the right choice of appropriate top-load fixtures.

Top-load tests need to be performed so that they are representative of the packaging as it is used.

For example, empty plastic bottles need to withstand the counter-pressure applied during the filling and capping process, so are often tested with a non-vented fixture until a deformation of 3.75mm (0.15").

Plastic bottles, which have been filled and capped, are top-load tested to calculate the number of pallets that can be stacked, so they are tested to a greater deflection of 6.35mm (0.25"). Source: ISBT - Voluntary Test Methods for PET Bottles

The calculation of top-load strength is expressed as a result in newtons (N) or pounds-force (lbf) and is typically accompanied by the deflection point at which the peak load occurs.

A detailed profile of the force/deflection curve gives a clear identification of any failure point allowing the operator to annotate and record where the bottle failed (eg crushed foot, shoulder dent, etc).

Mecmesin's range of Top-Load Testers are designed for bench-top use so occupy little worktop space.

They are available in various load ratings and sizes depending on whether you are testing small or bulky containers.

Mecmesin also have a great deal of experience in delivering customised solutions for unusual packaging profiles..

Related top-load testing methods

- Box crush (BCT)

- Edge crush (ECT)

- Ring crush (RCT)

- Top-load (column) crush

OmniTest TouchAutomated Top-load Tester (single-column)

Automated top-load tester powered by VectorPro test software from a touchscreen console.

Single-column bench-top model up to 7.5 kN

- Finished product and component testing

- Quality Control environments

- Production line integration

- Research and Development labs

Automated top-load tester powered by VectorPro test software from your own computer or tablet.

Single-column bench-top model up to 7.5 kN

- Product and component testing

- Quality Control environments

- Production line integration

- Research and Development labs

Automated top-load tester powered by VectorPro test software from a touchscreen console.

Single-column bench-top model up to 7.5 kN

- Finished product and component testing

- Quality Control environments

- Production line integration

- Research and Development labs

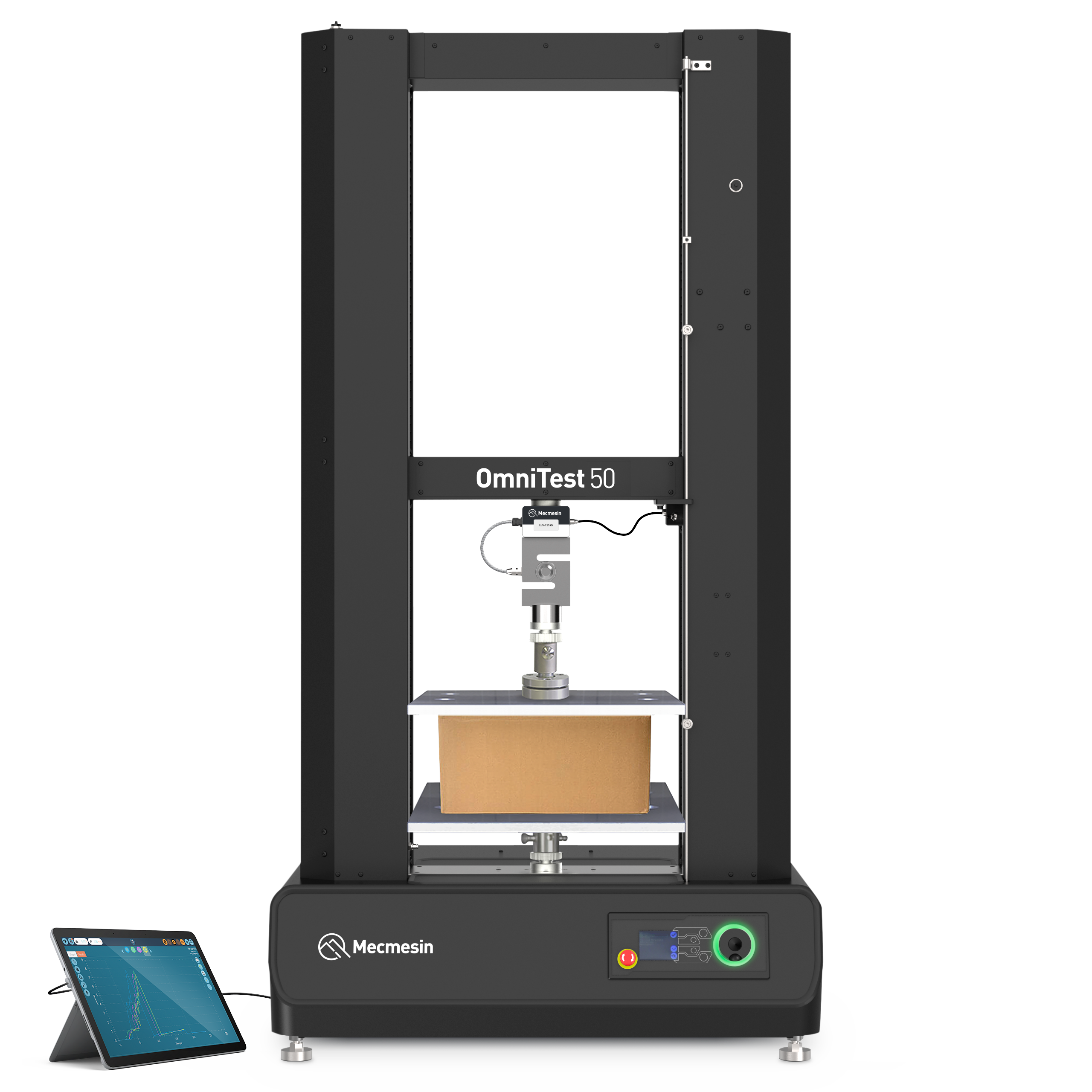

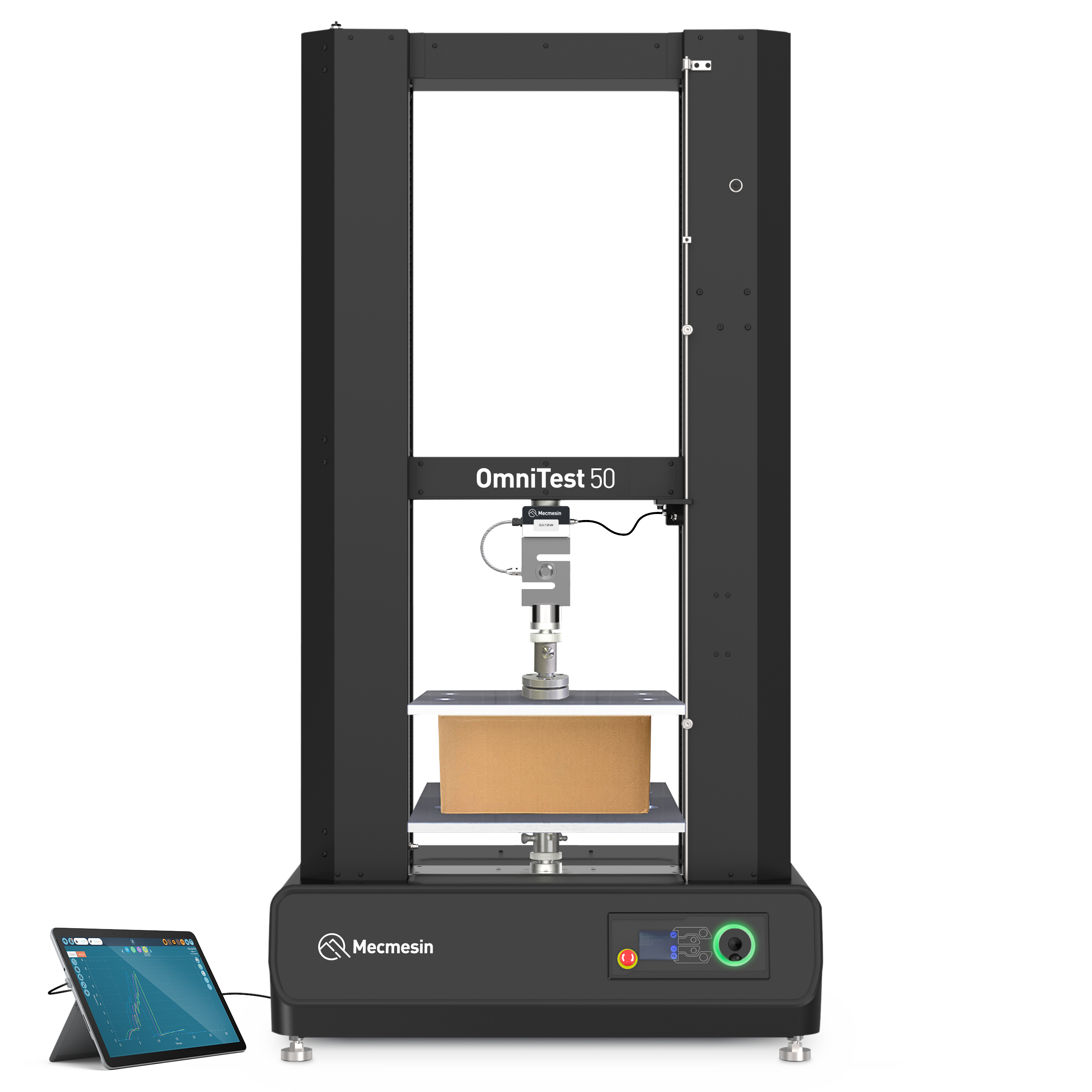

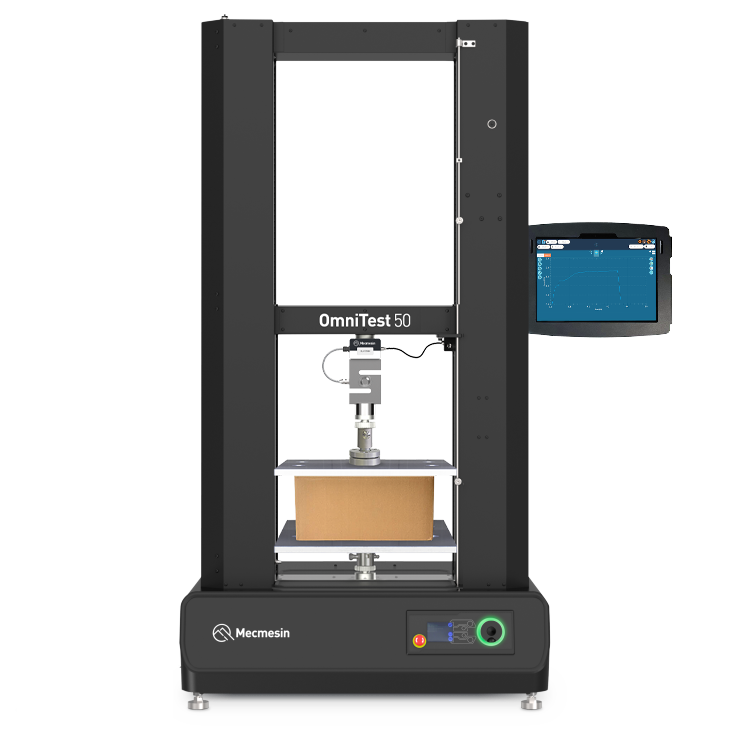

OmniTest 10/25/50Automated Top-load Tester (twin-column)

Mecmesin's OmniTest Touch systems are easy to use automated top-load testers, powered by VectorPro software running on your own PC.

Twin-column model up to 50kN

- Finished product and component testing

- Quality Control environments

- Production line integration

- Research and Development labs

Measure tensile and compressive forces from 2 N to 50 kN.

Mecmesin's OmniTest Touch systems are easy to use standalone solutions featuring an integrated touchscreen console pre-installed with VectorPro testing software .

Customers and operators love the simple touchscreen interface for accurate and reliable tensile testing on the production line and in quality control areas.

Mecmesin's OmniTest Touch systems are easy to use automated top-load testers, powered by VectorPro software running on your own PC.

Twin-column model up to 50kN

- Finished product and component testing

- Quality Control environments

- Production line integration

- Research and Development labs

OmniTestSingle-column universal test machine (UTM)

A versatile and easy to use universal tester powered by our newly developed materials testing software, VectorPro.

- Quality control environments

- Research and development labs

- Capacities:

0.5/1/2.5/5/7.5 kN - Materials tension and compression

- Contact and non-contact extensometers

Higher capacities are available in our OmniTest twin-column on www.mecmesin.com.

You might also be interested in...Closure Torque Testers

The VortexPro Touch is an advanced automated closure torque tester, powered by VectorPro test software from a touch-screen console. Rated up to 10 N.m (90 lbf.in) it is accurate, easy-to-use and ideal for standalone use.

As an automated torque tester it eliminates the variability associated with manual test methods, making it the perfect solution for routine testing of a wide range of caps and closures.

The Tornado digital torque tester is ideally suited for basic testing of the application and removal torque on caps and closures.

Manually-operated, the Tornado range has 4 models with capacities ranging from 1.5 - 10 N.m to cover almost all closures types and sizes.

Its ability to detect the initial peak torque and subsequent bridge-break torque make it the instrument of choice for testing closures with tamper-evident seals.

You might also be interested in our range of torque and closure testers, from simple manually operated digital instruments to automated testing systems.

Mecmesin torque testers are the accepted testing solution in industries as diverse as food and drink, pharmaceutical, cosmetics, and automotive.

Got a question about this system? Get in touch and speak to one of our Technical Sales Engineers now...